Our team has successfully completed a series of essential maintenance tasks on the CAT 35 forklift. Here’s a detailed breakdown of the work performed:

Engine Oil Change:

• Lubrication Oil Replacement: We replaced the old diesel engine lubrication oil with high-quality oil to ensure smooth engine operation and extend the engine’s lifespan.

• Oil Filter Replacement: The oil filter was changed to maintain clean oil circulation and protect the engine from contaminants.

• Fuel Filter Replacement: A new fuel filter was installed to ensure clean fuel delivery, enhancing engine efficiency and performance.

• Air Filter Replacement: The air filter was replaced to guarantee optimal airflow to the engine, improving combustion and overall engine health.

Cooling System Repair:

• Cooling Fan Belt Replacement: The damaged engine cooling fan belt (#1410) was replaced. This belt is crucial for the proper functioning of the cooling system, preventing the engine from overheating and ensuring consistent performance.

Ignition Key Replacement:

• Ignition Switch Key Assembly Replacement: We installed a new ignition switch key assembly to address issues with the ignition system. This replacement ensures that the forklift starts reliably and securely, reducing downtime and operational interruptions.

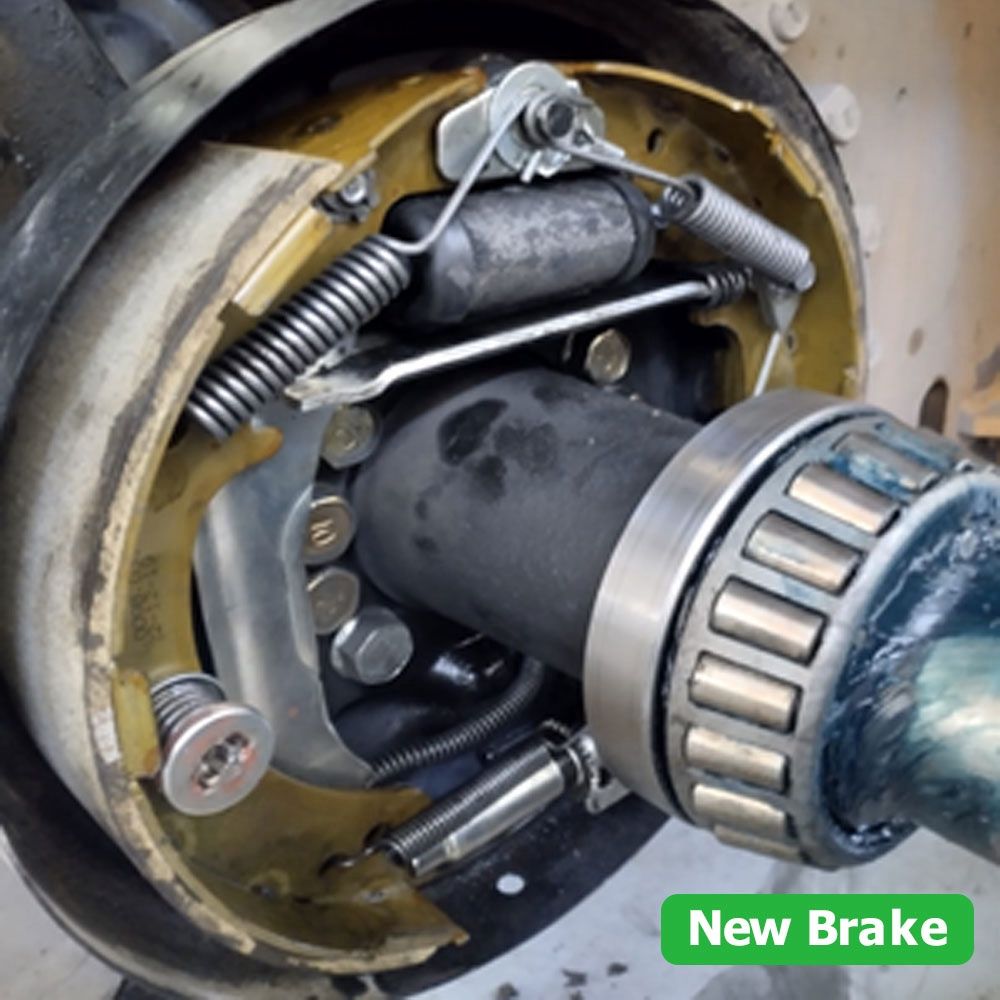

Brake System Repair:

• Brake Cylinder Seal Kit Replacement: The seal kit on the brake cylinder was replaced to fix any leaks and restore proper hydraulic pressure within the brake system.

• Brake Pads Replacement: New brake pads were installed to enhance braking efficiency and safety. This ensures that the forklift can stop effectively, protecting both the operator and the equipment.

Regular maintenance not only prolongs the lifespan of machinery but also ensures safety and optimal performance in our daily tasks.