The partnership between Spektr Group and Kinetics Controls & Innovation Ltd. marks a significant milestone in the oil and gas industry, particularly in Azerbaijan. Spektr Group, known for its expertise in providing cutting-edge technologies and services, is thrilled to join forces with Kinetics Controls & Innovation Ltd., a recognised leader in delivering innovative solutions tailored to the unique challenges of the oil and gas sector.

Azerbaijan, with its rich oil and gas reserves and strategic location, presents immense opportunities for collaboration and growth in the energy sector. By combining Spektr Group’s technical expertise and Kinetics Controls & Innovation Ltd.’s industry advancement and innovation, the partnership aims to leverage synergies and deliver comprehensive solutions that address the evolving needs of Azerbaijan’s oil and gas industry.

Spektr Group’s diverse portfolio of services, ranging from engineering and project management to technology deployment and support, complements Kinetics Controls & Innovation Ltd.’s expertise in unique products and services specifically designed to reduce costs and minimise downtime, whilst maintaining or increasing production across: subsea, surface, refinery, down hole, topside pipeline and other applications. Together, the two companies are poised to enhance operational efficiency, optimise production processes, and drive sustainable growth for their clients in Azerbaijan.

The partnership represents a commitment to innovation, excellence, and customer satisfaction. By pooling their resources, knowledge, and capabilities, Spektr Group and Kinetics Controls & Innovation Ltd. are well-positioned to provide end-to-end solutions that enable oil and gas companies in Azerbaijan to thrive in today’s dynamic market environment.

Overall, the collaboration between Spektr Group and Kinetics Controls & Innovation Ltd. holds great promise for advancing the oil and gas industry in Azerbaijan, fostering economic development, and contributing to the country’s energy security and sustainability objectives.

Their diverse range of services includes:

1. Wellhead Seal Isolations

Two-part, time-activated, various viscosity sealant which self-energises under differential pressure when cured. Bridges and isolates large gaps and holes in seal structures, unlike pressure-activated sealants which require small gaps and high pressures to activate.

Rigless isolations successfully deployed worldwide reinstating barriers to maintain safe and effective production.

- Reinstate tubing and casing void seals and pack-offs.

- Protect the environmental gasket between wellhead spools.

- Isolate lockdown screw packing.

- Safeguard failed injection fittings.

2. Siyirtmə klapanı izolyasiyası

One-part, non-curing, high viscous sealant product which is deployed into the valve cavity filling scores, scratches and damaged areas around the gate and seat area creating an isolation. Very effective alternative to plastic packing and ideal for re-energising damaged “P” seals.

- Isolate gate valves to allow intervention rig up.

- Provides a repeatable isolation for failed valve stem packing leaks.

- Remains in the valve cavity much longer than grease.

- Protects against well debris and corrosive fluids.

- Operational temperature of -50° to +250°C.

- Displace and replace valve grease providing a superior high-temperature lubricant.

- No Issues with future valve operating torque, production flow, wireline or coiled tubing activity

3. Packer and Casing Shoe Isolations

Time-activated sealant. Cures to soft flexible gel material. High compression value but a low torsion/tear threshold. Designed and ormulated to provide isolations within annuli preventing well fluid migration. The sealant is weighted to sink through existing annuli fluids. Small volumes required, no squeezing or bull heading required.

- Production packer element damage isolation.

- Damaged cement shoe isolation.

- Repair micro annuli or porosity issues.

- Small footprint, hand-portable air driven tooling.

- Operational Temperature of -5° to +175°C.

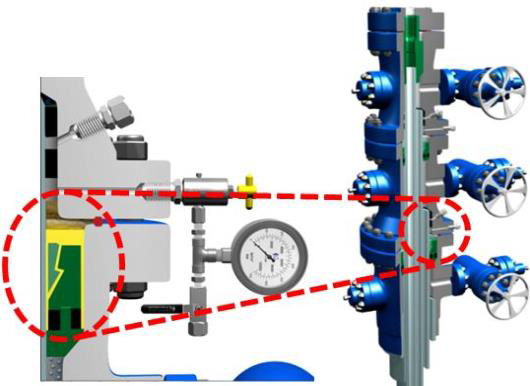

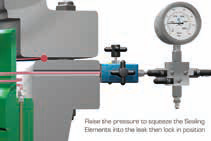

4. Control Line Leak Repair

One-part, non-curing gel sealant product designed to isolate hydraulic control line leaks in downhole safety valve (DHSV) control line compression fittings where the hydraulic fluid is leaking out of the system while under pressure.

- Maintains the functionality of a downhole safety valve (DHSV).

- A genuine alternative to pressureactivated sealants.

- Neutrally buoyant and will remain in a suspended position.

- Successfully pressure tested up to 10,000psi.

- Operational temperature -50°C to +175°C.

- Expected lifespan of 25 years if left undisturbed.

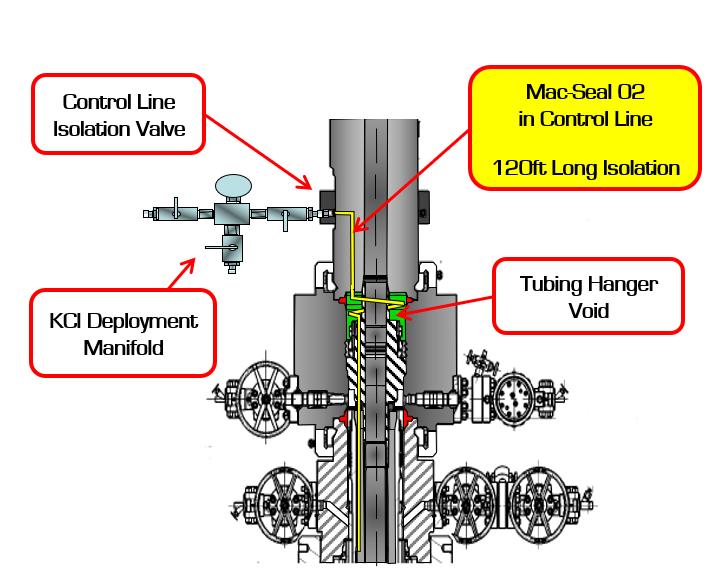

5. Control Line Plugging

Two-part, time-activated sealant which self-energises under differential pressure when cured. Control line plugging is used to reduce rig time and increase safety when pulling completions for workover or abandonment.

- The sealant is used on control lines, creating plugs to completely block and isolate the line.

- This application can be deployed at the same time as ongoing deep set plugging operations – “Sim Ops”.

- Cures to a solid yet flexible material.

- Successfully pressure tested up to 10,000psi.

- Operational temperature -50°C to +250°C.

- Expected lifespan of 25 years if left undisturbed.

6. Pipeline and Process Valve Isolations

Failed isolations can be detrimental to your operation, causing you delays and downtime. There is no need to have a lack of barriers delay your inspection, repair and maintenance programme. Reduce your delays and get production back online with our fully engineered pipeline and process valve isolations. At KCI we understand the pressure operators are under to maintain assets and reinstate valuable production.

As it becomes increasingly more difficult to obtain isolations on ageing valves, KCI’s fully engineered pipeline and process valve isolations will help to minimise downtime and reinstate valuable production safely and effectively.

- Engineering-led leak sealing solutions.

- Successfully reducing downtime since 2002.

- In-depth inspection and investigation of every project.

Other innovative solutions to support complex problems which may be difficult to resolve with conventional methods or technologies.

Ring Gasket Groove Repair

Mac-Seal 06 offers a quick, safe, robust, and cost-effective solution. Time-activated and available in various viscosities depending on your requirements.

- Sealant is quick to prepare and can be installed by the team on site with minimum downtime.

- Mix and apply Mac-Seal 06 to the upward-facing flange.

- Install the gasket and press to displace the sealant.

- Remove excess and reposition inside the gasket.

- Apply Mac-Seal to the downward-facing flange.

- Mate the two flanges together and tighten.

- The upper and lower flange sealant

meet, bond and cure to create a single isolation. - Pressure testing can take place after the sealant has cured.

Partnering with KCI empowers us to deliver cutting-edge solutions and enhance our capabilities in the energy sector. Together, we’re committed to driving innovation and excellence in every project we undertake.