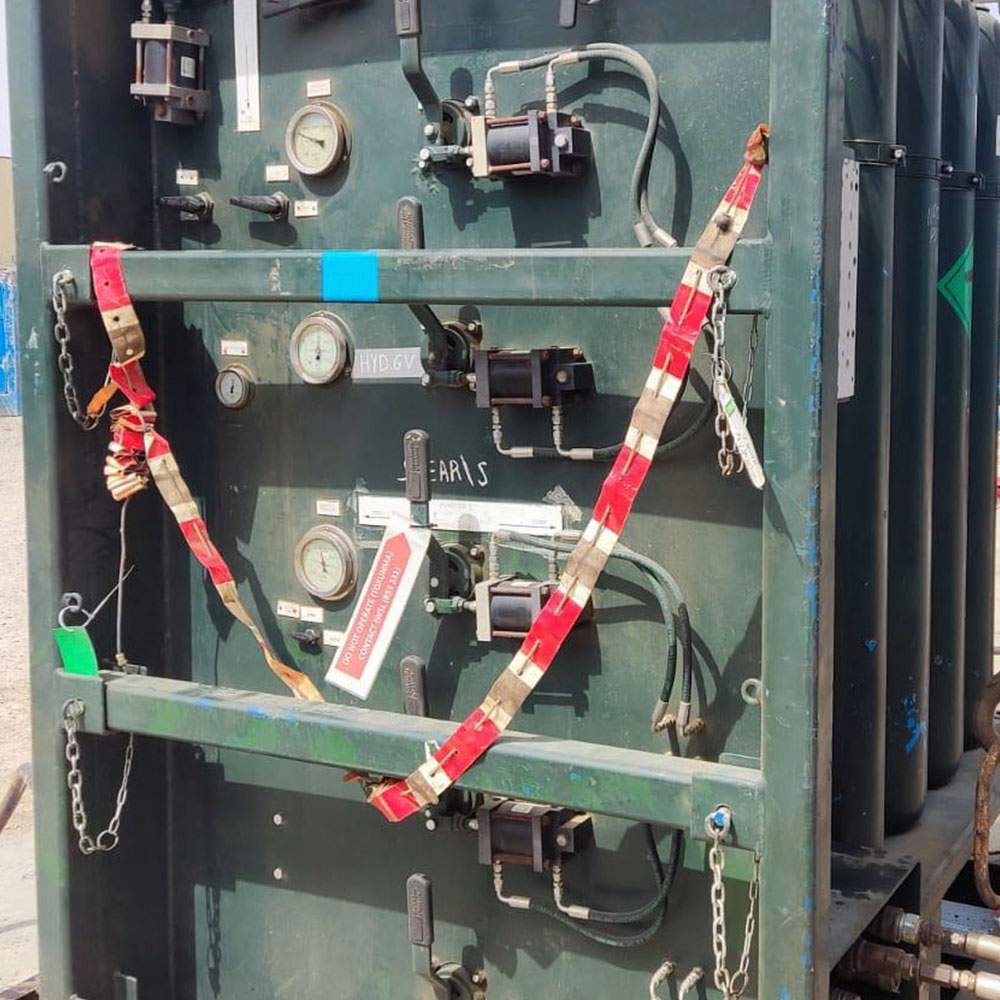

We’re thrilled to share a recent successful maintenance project carried out on the Koomey unit! Our team’s dedication and expertise ensured that the unit is back to optimal operational condition, ready to deliver outstanding performance.

Tubing Replacement Process:

- Disassembly:

- Hydraulic Tubing Dismantling: Carefully detached high pressure hydraulic tubes from the unit.

- Component Disconnection: Involved the disconnection of a 1” tee, elbow, and union to prepare for the new installation.

- Fabrication:

- New Stainless Steel Tubes: Fabricated new stainless steel tubes (Pipe A), complete with swivel nuts and glands.

- Expert Flaring: Used a flaring machine to expertly flare the pipe ends, ensuring a perfect fit and secure connections.

- Assembly:

- Tubes Installation: Assembled the newly fabricated tubes onto the Koomey unit, ensuring precise alignment and secure attachment.

- Function Test:

- High-Pressure Testing: Conducted a rigorous functional test post-installation, subjecting the tubes and fittings to 3000 PSI for one hour.

- Performance Verification: This high-pressure test verified the integrity and functionality of the new installations, ensuring the Koomey unit operates flawlessly.

Our meticulous process underscores our commitment to excellence in equipment maintenance. The Koomey unit is now equipped to deliver reliable and efficient performance, thanks to our skilled team and thorough testing procedures.