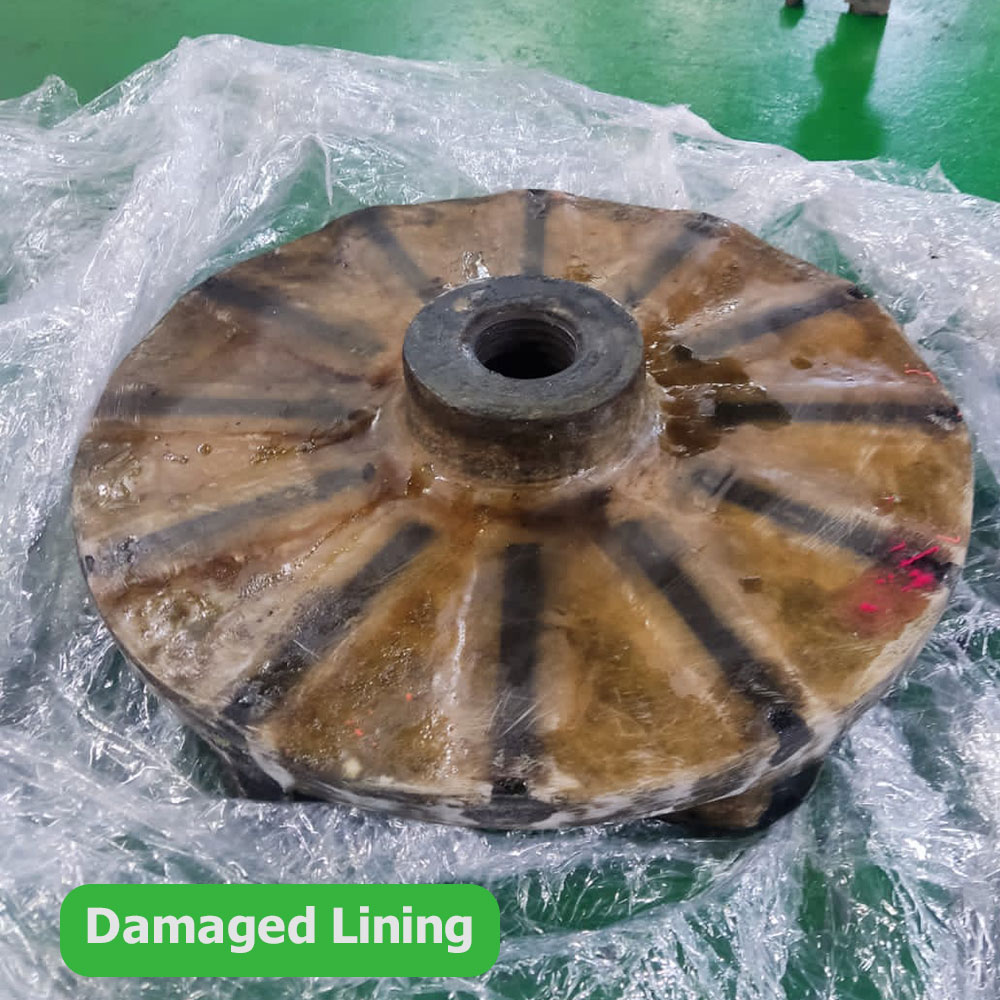

In our commitment to excellence, Spektr Group executed a meticulous repair job during the impeller lining restoration of a pump. Here’s an insight into the precision process:

Washing and Cleaning:

The impeller underwent a thorough washing and cleaning process. This initial step is crucial to eliminate any debris, contaminants, or residue that might hinder the subsequent repair.

Application of High-Density Polyethylene (HDPE):

To reinforce the worn areas of the impeller, we employed High-Density Polyethylene (HDPE), specifically HD 3840 UA. This practice is standard for repairing surfaces, especially in applications where abrasion resistance is paramount.

Surplus Removal and Final Cleaning:

Post-application of HDPE, surplus material was meticulously removed. A final cleaning ensured precision in the repair, eliminating any excess materials that could potentially impact the impeller’s optimal functionality.

At Spektr Group, our maintenance and repair processes are a testament to our unwavering dedication to precision and quality. We believe in going beyond expectations to ensure that every component operates at its best.