Spektr Group has successfully completed maintenance and repair work on a forklift, ensuring its safety, reliability, and optimal performance. The scope of work included replacing the brake system cable and servicing key components to enhance functionality.

Scope of Work:

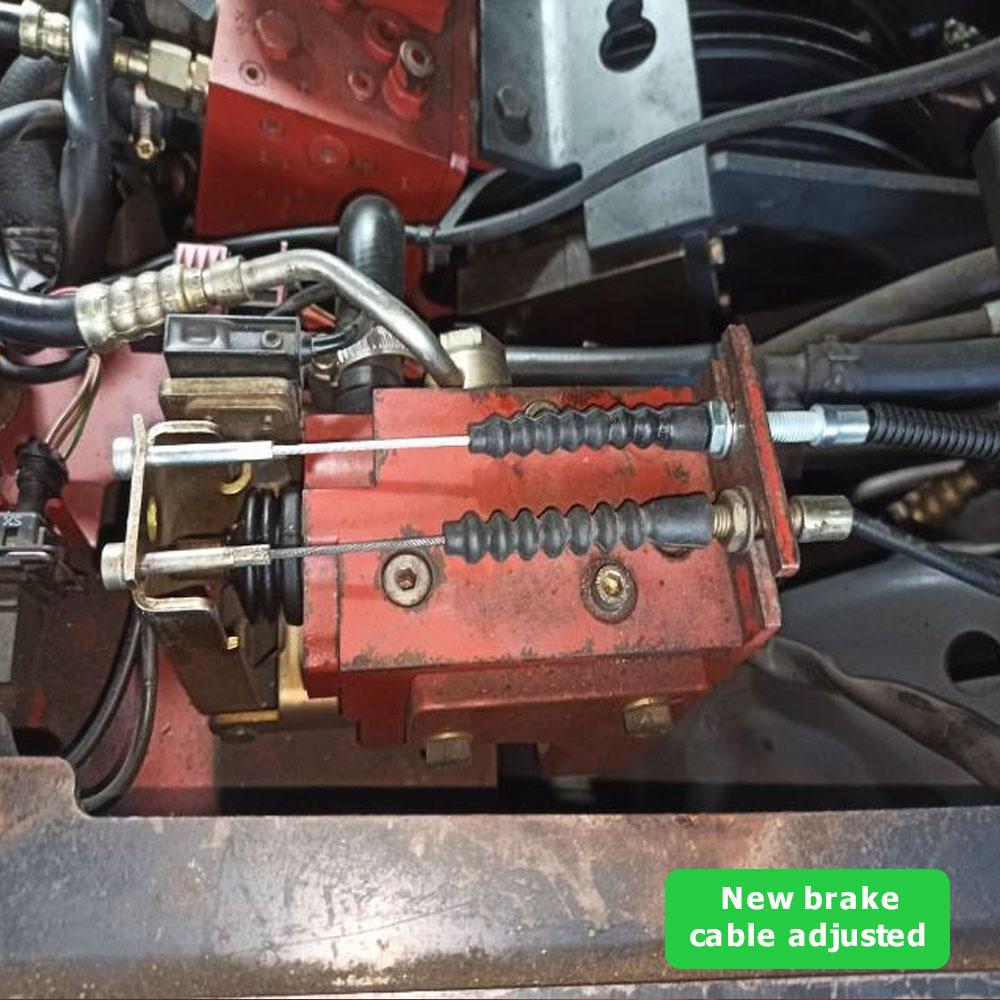

Brake System Cable Replacement

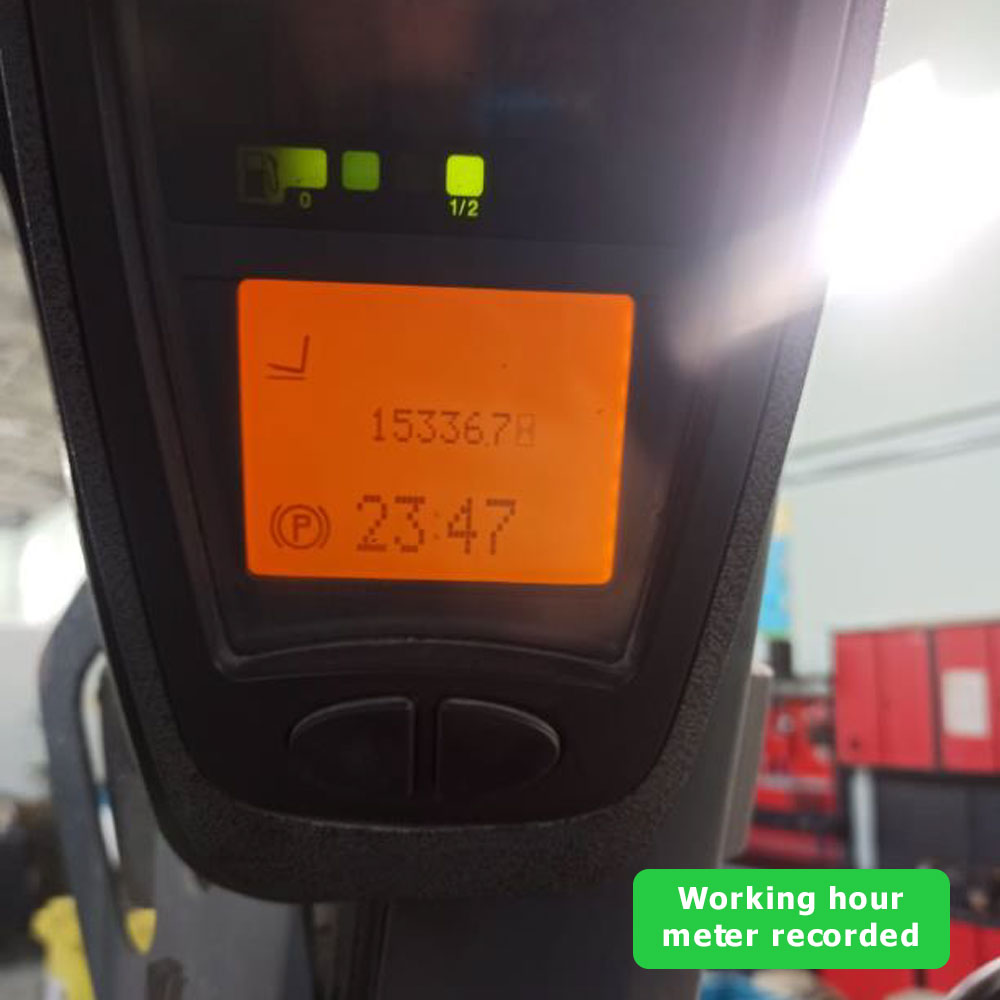

∙ Hour Meter Measurement – Initial assessment of the forklift’s runtime for maintenance scheduling.

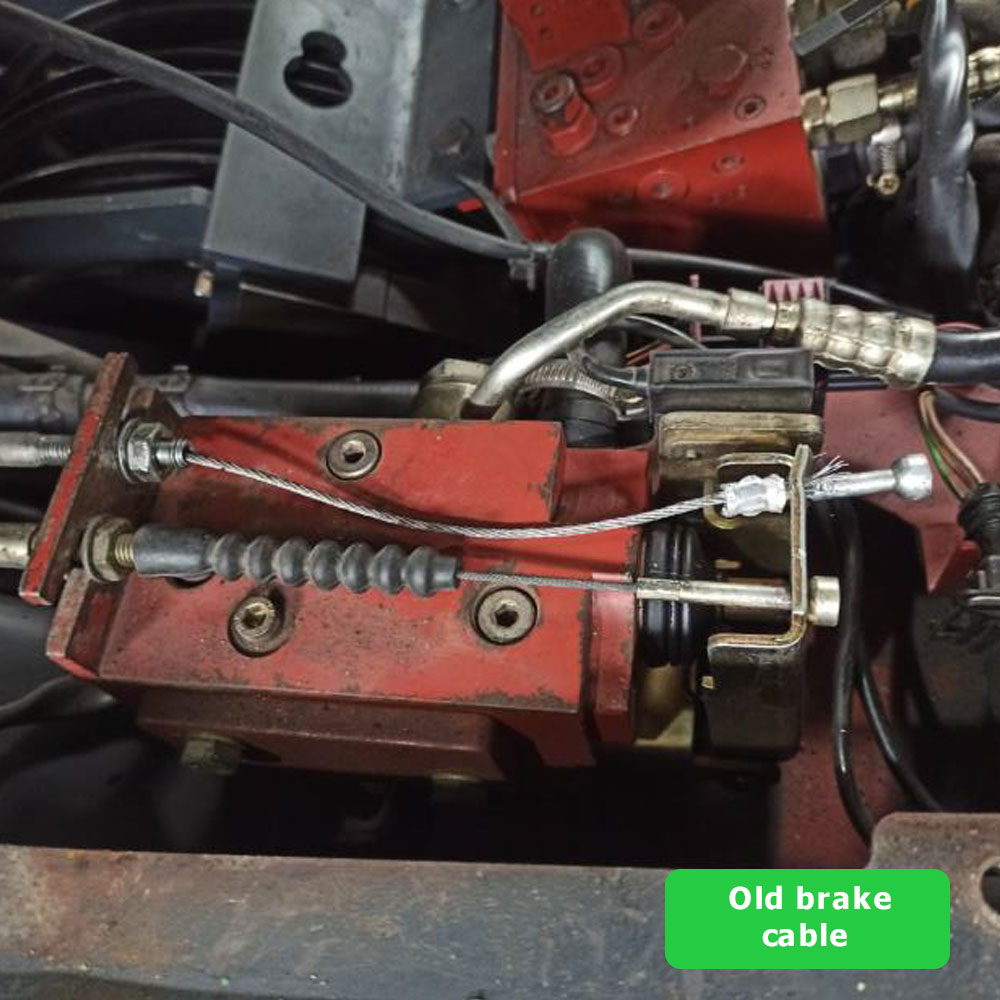

∙ Protective Cover Removal – Removed the necessary components to access the damaged cable.

∙ Old Brake Cable Removal – Successfully detached and removed the worn-out brake cable.

∙ New Brake Cable Installation & Adjustment – Installed a high-quality replacement brake cable, properly adjusted for precise braking performance.

∙ System Reassembly & Testing – Ensured all components were securely reinstalled, followed by functional testing to verify smooth operation and braking efficiency.

Servicing of Key Components

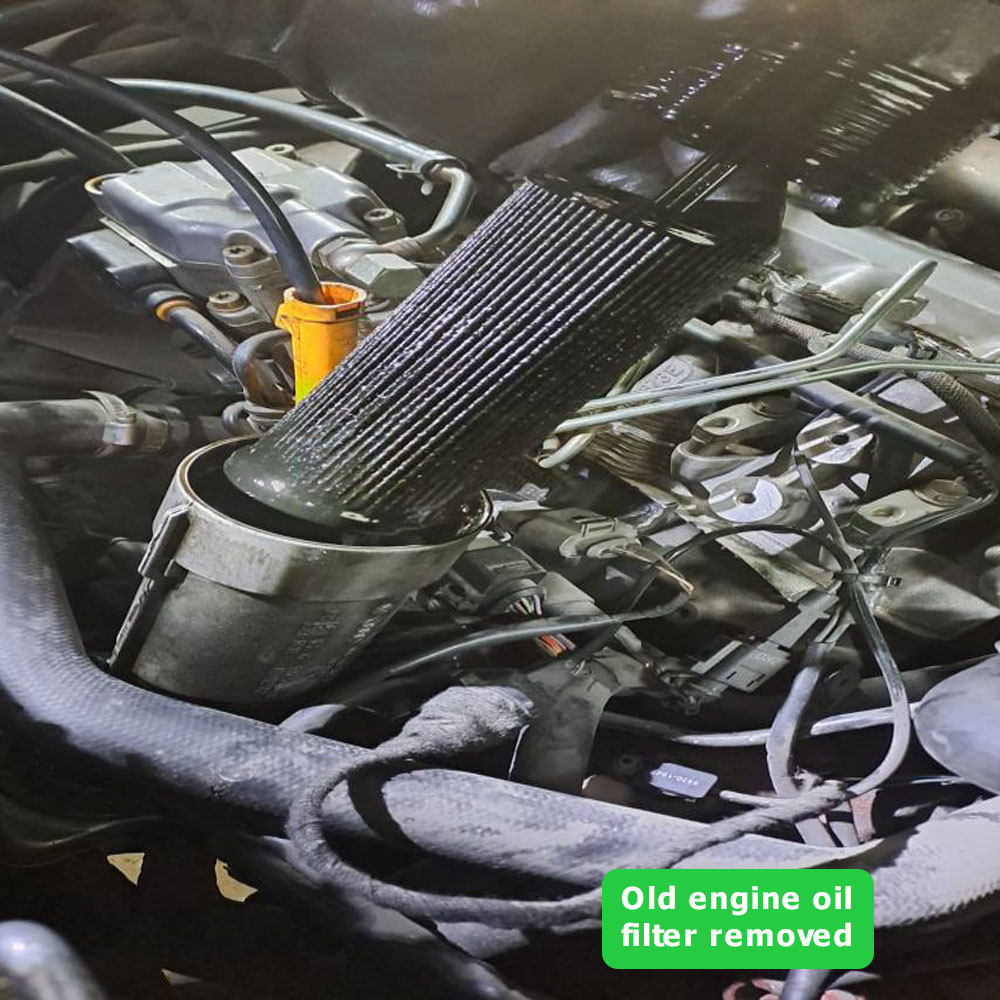

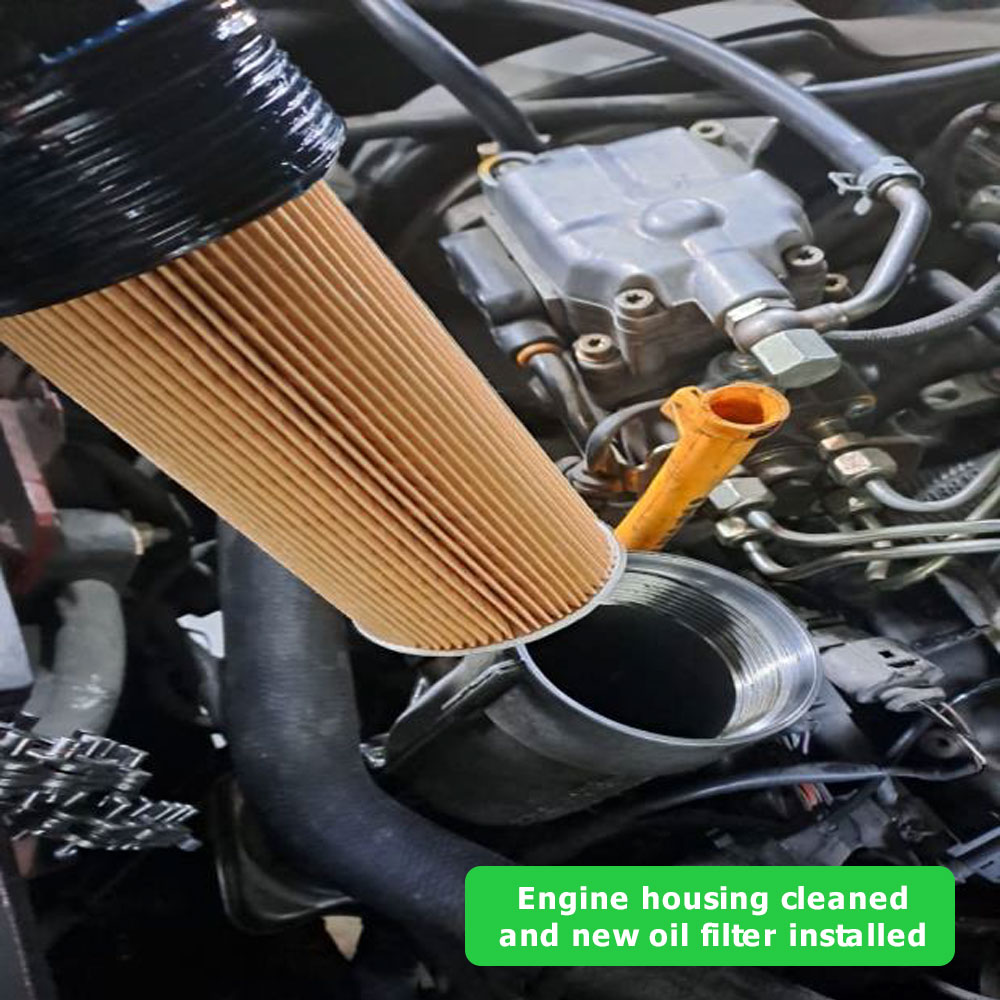

∙ Engine Oil & Filter Replacement: Removed the old oil filter, replaced it with a new one, and changed the engine oil to fresh 15W40 to ensure smooth lubrication and extended engine life.

∙ Fuel Filter: The worn-out fuel filter was replaced to ensure a steady and contaminant-free fuel supply for improved engine performance.

Key Benefits of Maintenance:

∙ Enhanced braking efficiency for improved safety.

∙ Extended engine lifespan with proper lubrication and filtration.

∙ Reduced downtime by ensuring smooth forklift operations.

∙ Compliance with maintenance standards for optimal performance.

With this successful maintenance, the forklift is now fully operational and ready for continued use in demanding environments.