At Spektr Group, precision and reliability are paramount in our maintenance services. We’re pleased to share our recent success in addressing overheating issues with the Cummins QSM11 diesel engine, ensuring optimal performance for our clients.

Maintenance and Repair Process:

- Cleaning Strainer: Ensured uninterrupted coolant flow by meticulously cleaning the strainer on the engine cooling line, preventing potential blockages.

- Pressure Valve Repair: Rectified cooling system regulation by repairing the solenoid-operated valve, essential for maintaining optimal pressure levels.

- Valve Installation: Successfully reinstated the repaired valve into the engine cooling line, restoring proper system functionality.

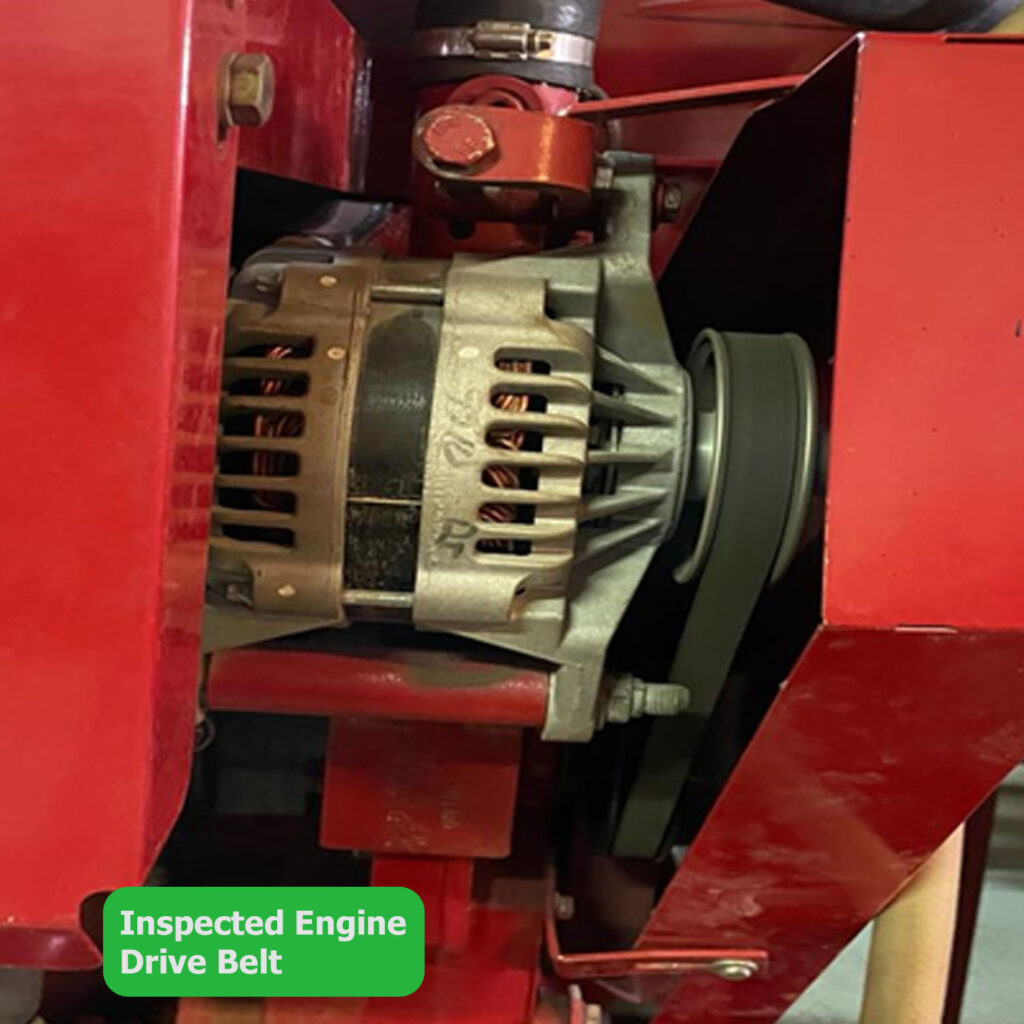

- Functional Run and Temperature Check: Conducted a thorough 30-minute engine test to monitor performance and detect overheating signs. Achieved stable coolant temperature at 83°C, indicating successful repairs. Additionally, inspected the engine drive belt for wear and tear.

- Coolant Replacement: Identified suboptimal coolant quality and recommended replacement to uphold the engine heating system’s efficiency and prevent potential issues.

Our meticulous approach ensures the reliability and longevity of your equipment. Trust Spektr Group for top-tier maintenance solutions tailored to your needs.