At Spektr Group, precision is our promise, and our machining process for 18-inch flange faces exemplifies our commitment to excellence.

Here’s an overview of our meticulous procedure:

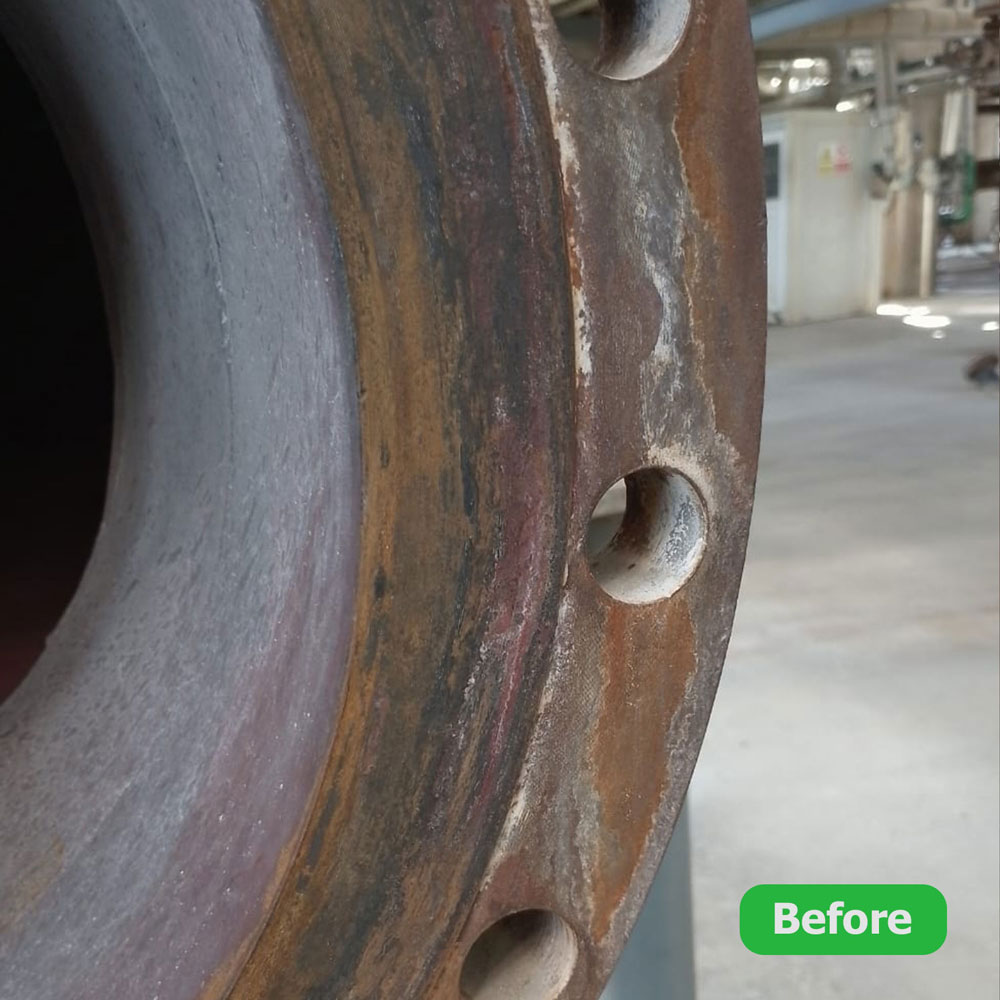

- Initial Inspection: We begin by thoroughly inspecting the flange face to assess its condition and identify any imperfections.

- Surface Preparation: Prior to machining, we ensure the surface is clean and free from debris, providing an optimal working environment.

- Precision Machining: Our state-of-the-art machining equipment meticulously mills the flange face to exact specifications, achieving smoothness and uniformity.

- Quality Checks: Throughout the machining process, we conduct rigorous quality checks to verify dimensional accuracy and surface finish.

- Final Inspection: Once machining is complete, a final inspection is performed to ensure the flange face meets our stringent quality standards.

- Surface Protection: To preserve the integrity of the machined surface, we apply protective coatings or treatments as necessary.

- Reporting: A thorough reporting form is being submitted to Customer outlining initial flange condition and after the machining process, indicating all tolerances required by relevant standards.

With our expertise and attention to detail, you can trust Spektr Group for flawless flange face machining, ensuring reliability and performance in your operations.