In our unwavering commitment to safety, Spektr Group recently conducted a comprehensive inspection and testing regimen on a Breathing Apparatus (BA) Trolley and Cylinders. The following actions were thoroughly executed to ensure the utmost reliability and integrity of this safety critical equipment:

1. Trolley Frame Inspection:

The foundation of mobility, the trolley frame, underwent a meticulous examination. Every aspect, from the general condition to welding points and tire integrity, was scrutinized to ensure optimal performance.

2. BA Hose Pressure Test:

To ensure the integrity of the breathing apparatus hoses, each of them has passed a separate pressure test. Certificates have been issued to confirm the outmost performance of hoses.

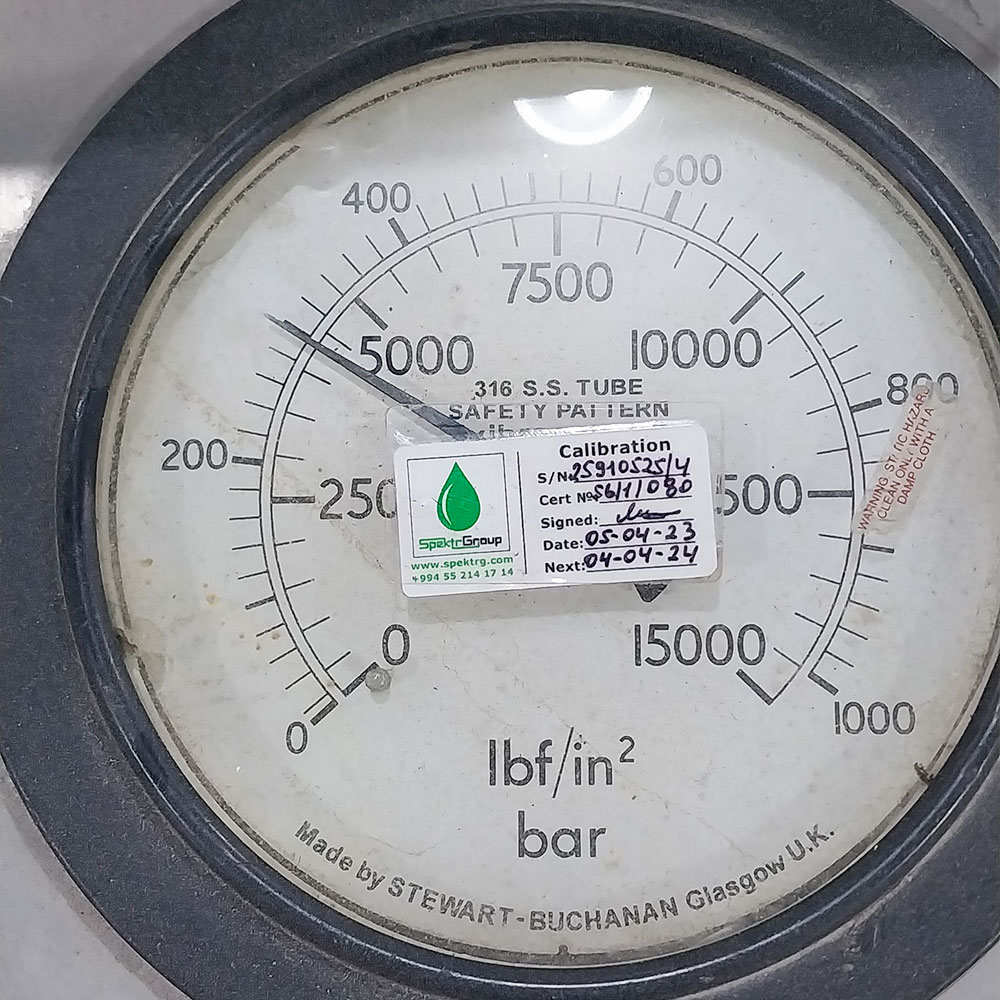

3. Indicator Gauge Testing:

The critical indicator gauges, fundamental for accurate readings, were rigorously tested. This will ensure that 200 bar and 11 bar gauges will demonstrate their reliability even in challenging conditions.

4. Functional Inspection of Connection Hoses and Valves:

The lifelines of the system, the connection hoses, and valves were subjected to a thorough functional inspection. This ensured that each component operates seamlessly, contributing to the overall reliability of the breathing apparatus.

5. Breathing Apparatus Cylinder Body Test:

The core of the breathing apparatus, the cylinder body, underwent a stringent examination. Through thorough visual inspection and enduring a pressure test of 450 bar, this assessment reaffirmed the structural integrity and reliability of this crucial component.

6. BA Cylinder Valve Leak Test:

Leakage is not an option when it comes to safety. The breathing apparatus cylinder valve underwent a stringent leak test and impressively sustained a pressure of 300 bars without any signs of leakage, ensuring their reliability in critical situations.

7. Inspection of Low-Pressure Hoses:

The often-overlooked 3/8-inch low-pressure hoses were given due attention. Each hose was meticulously inspected to ensure its functionality, leaving no room for compromise in the overall safety of the breathing apparatus.

These actions signify our commitment to safety excellence at Spektr Group, even when dealing with equipment not directly our own. Stay tuned for more updates on our unwavering journey of precision and safety.