At Spektr Group, our commitment to excellence shines through in every inspection, maintenance, and repair task. Here’s a detailed overview of the recent meticulous work performed on 200-ton Anchor Handling/Towing Winch:

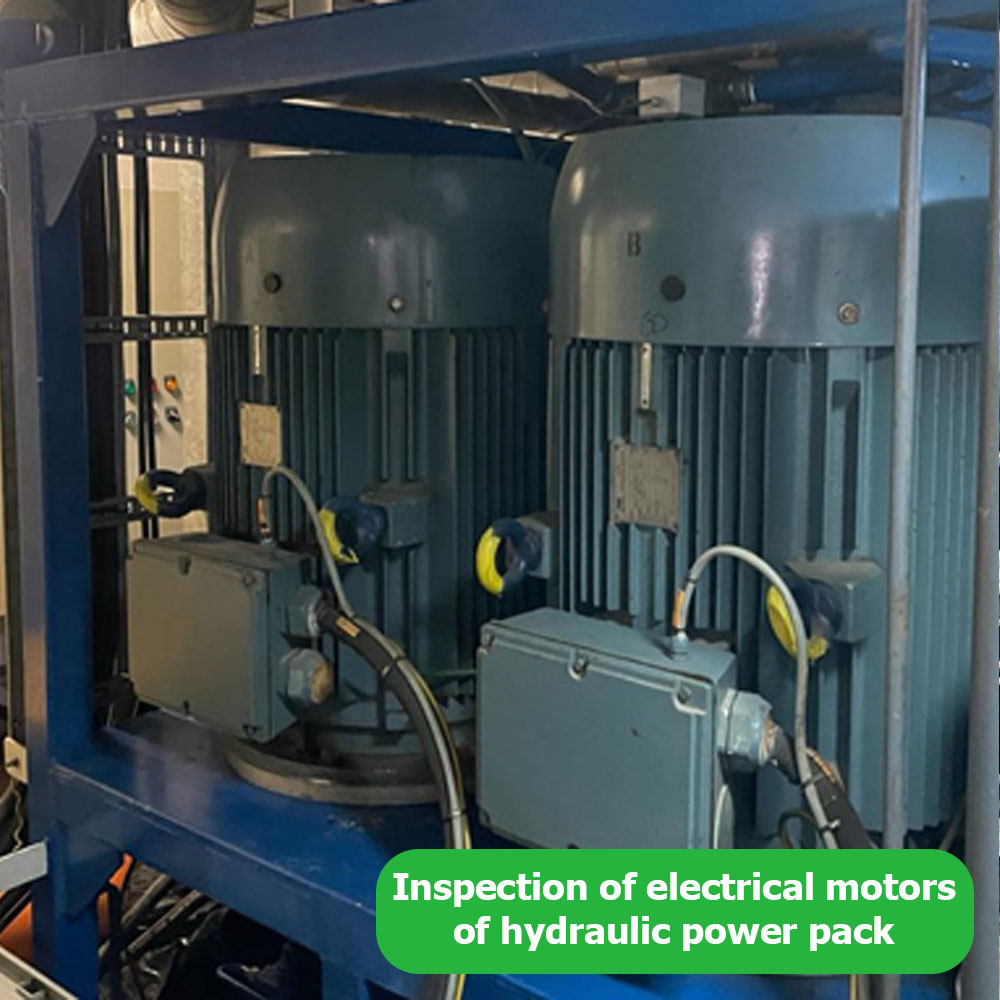

Hydraulic System Inspection:

During the inspection of the Hydraulic Power Pack Station, issues with the pressure sensor (250 bar, 4-20mA) were identified. We promptly replaced the damaged sensor and adjusted hydraulic system pressure to meet manufacturer requirements.

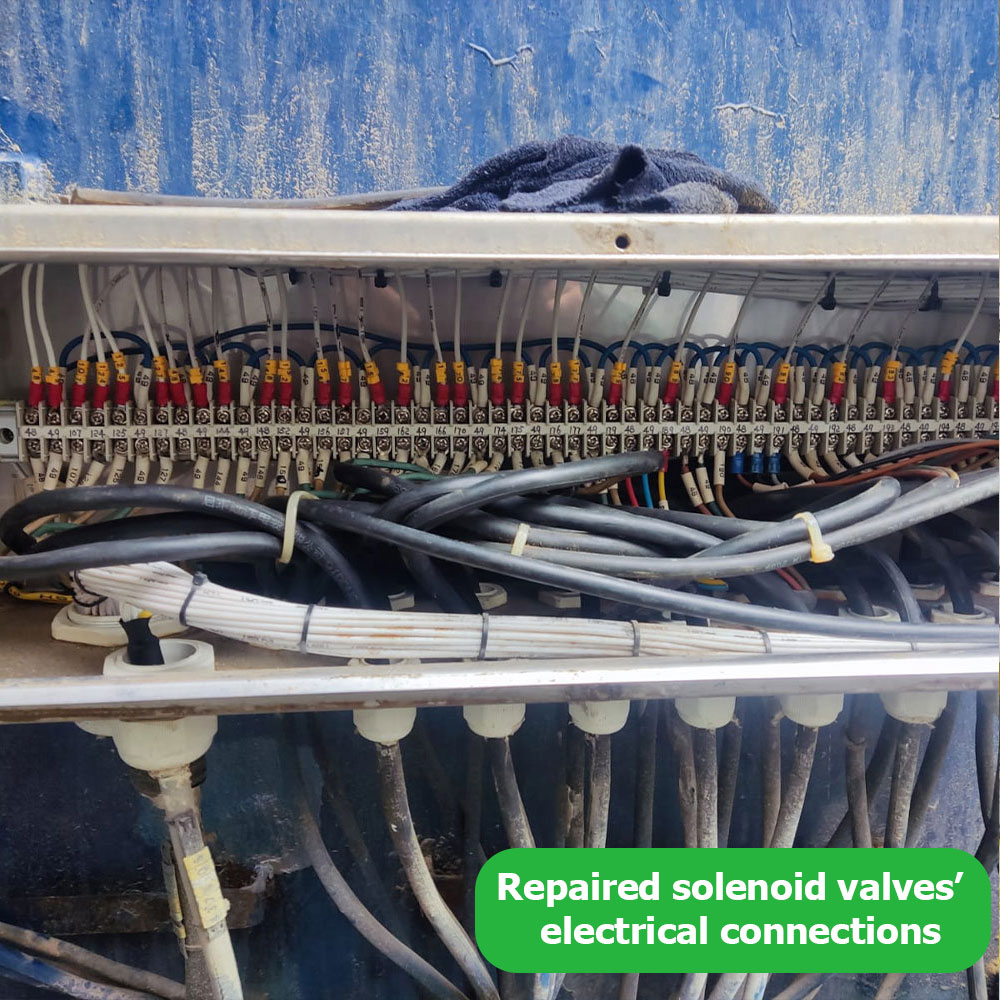

Hydraulic Directional Control Valve Inspection:

Thirteen directional control valves were thoroughly examined, revealing malfunctions in third winch speed control solenoids and three main block valves. A decision was made to disassemble and repair the valve assembly.

Hydraulic Cylinders:

Hydraulic cylinders for the Upper winch, Lower winch, and Gypsy winches underwent a meticulous inspection. We verified proper functionality, checked for damages and leaks, and manually adjusted the brake band on the cylinders using a threaded rod.

Electrical Control Panel Inspection:

A comprehensive inspection of all electronic systems was conducted, identifying malfunctions. The brake system malfunction was troubleshooted, and issues with the Emergency release system were resolved. All electrical circuits were restored according to manufacturer drawings.

Function Test:

A rigorous function test was carried out on all units (Upper, Lower, and Gypsies) after troubleshooting defects. Faulty operation on the third-speed direction control valve was identified and is set to be replaced for proper speed operation.

At Spektr Group, we leave no stone unturned in ensuring the optimal performance and reliability of our equipment.