We’re pleased to share the successful completion of several critical maintenance tasks aimed at improving operational efficiency, safety, and reliability. Here’s a breakdown of the work we’ve done:

- Provision and Installation of Clamp on Muffler

- Objective: Secured a new clamp on the muffler to ensure stability and minimize movement during operation.

- Process: The muffler area was inspected for optimal clamp positioning, and a compatible, high-strength clamp was installed and tested under operational conditions.

- Result: Clamp securely fastened, muffler stability confirmed. Periodic inspection recommended to ensure the clamp remains secure.

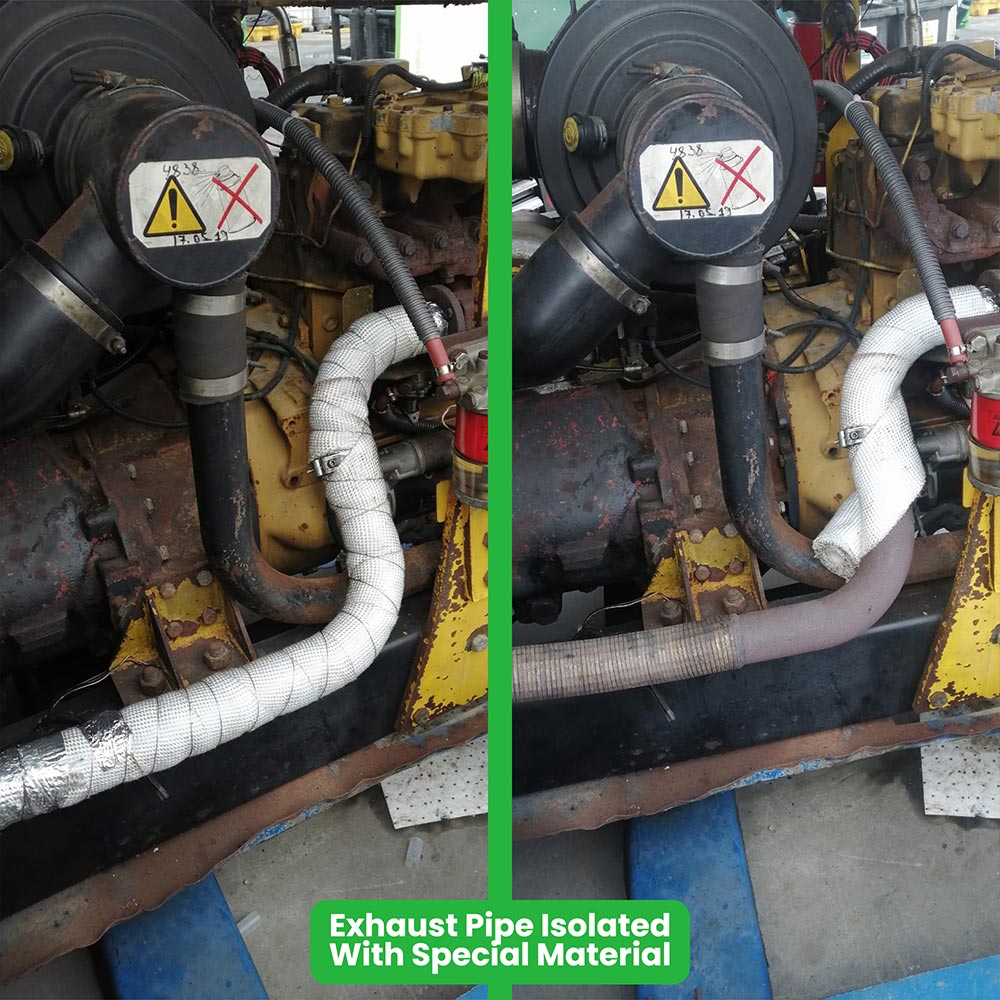

- Insulation on Muffler

- Objective: Added insulation around the muffler to reduce external heat and noise.

- Process: High-quality insulation materials were selected and carefully applied without obstructing airflow or affecting performance.

- Result: Effective reduction in heat and noise as verified in an operational trial. Insulation integrity will be checked in the next routine inspection.

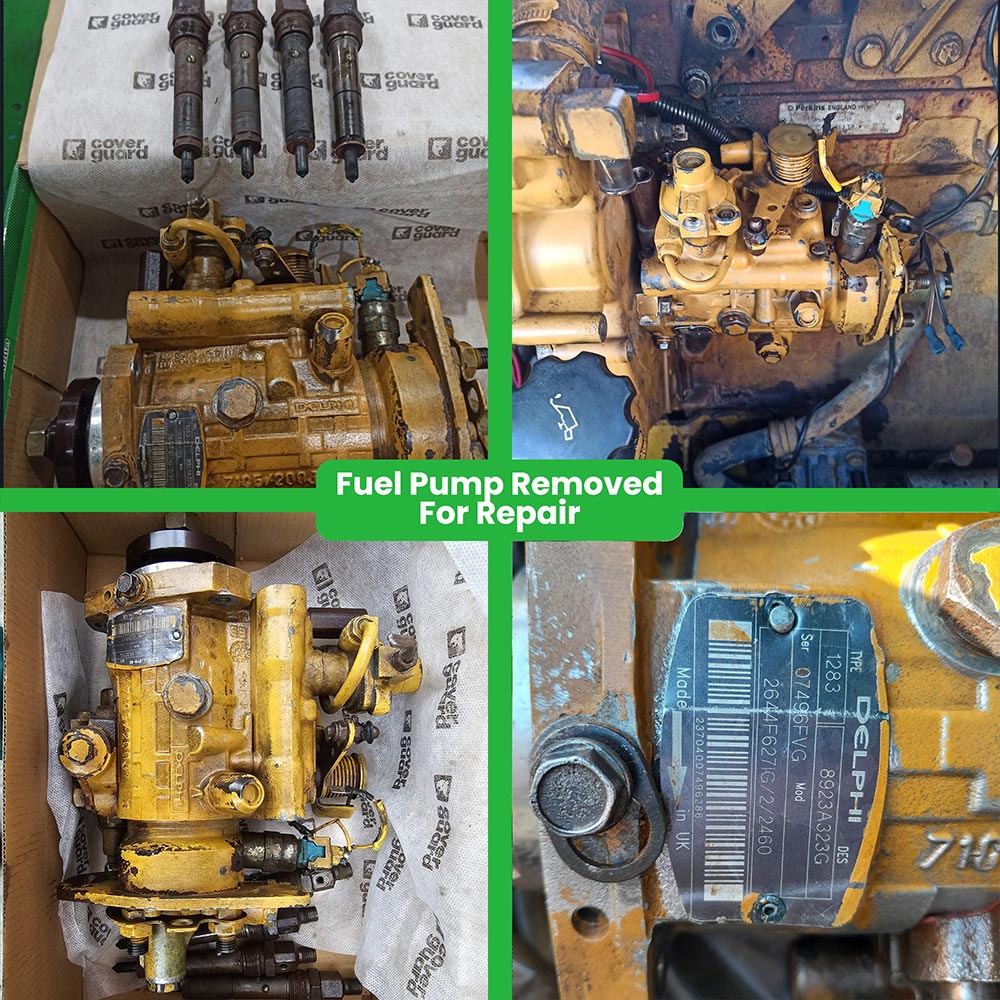

- Fuel Pump Leak Repair

- Objective: Resolved a fuel pump leak to maintain system integrity and prevent fuel seepage.

- Process: The pump was disassembled, inspected, and repaired, with any worn components replaced. It was reassembled and tested under pressurized conditions.

- Result: Leak resolved; pump operating optimally. Seals will be monitored in future inspections.

- Repair of Two Air Regulator Solenoid Valves

- Objective: Restored functionality to two air regulator solenoid valves.

- Process: Valves were isolated, cleaned, and repaired, with defective parts replaced as needed.

- Result: Valves are now fully operational, with functionality confirmed through testing. Routine testing will continue.

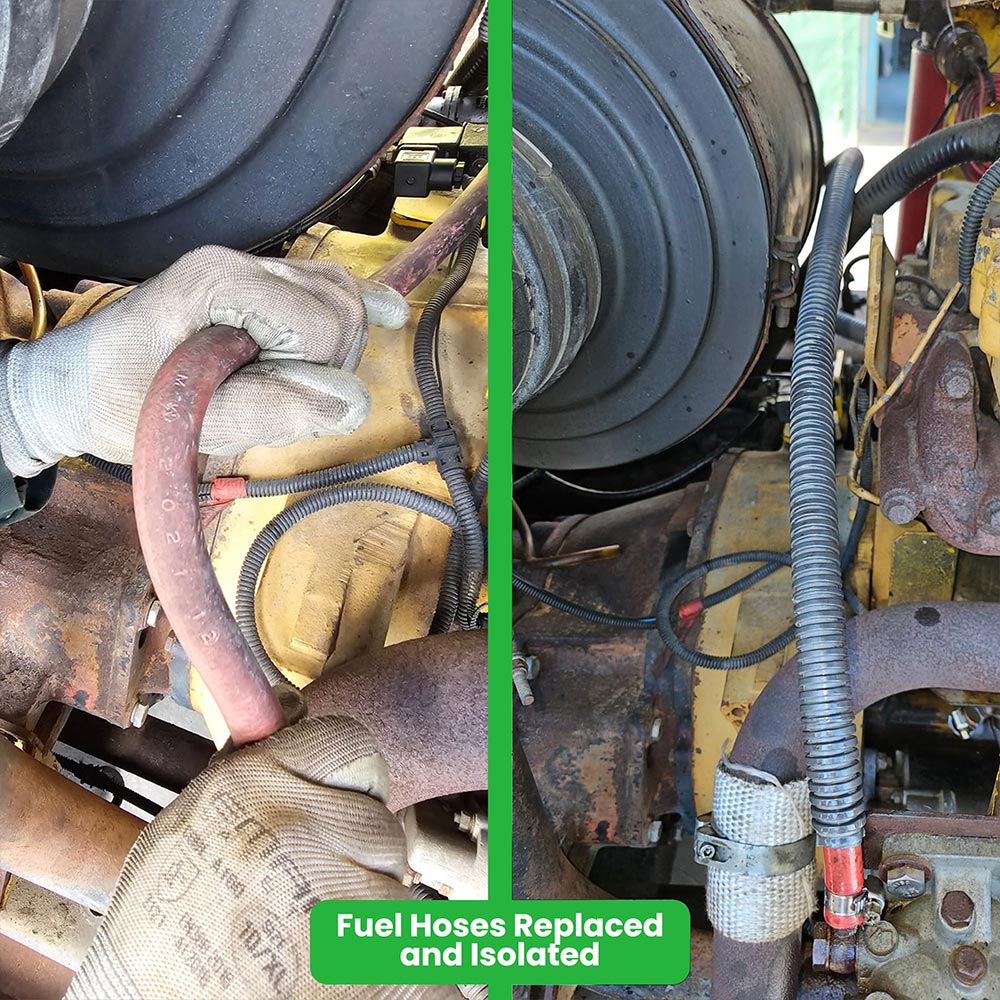

- Provision and Replacement of Two Fuel Hoses

- Objective: Prevented potential leaks by replacing two worn fuel hoses.

- Process: Worn hoses were identified, removed, and replaced with secure, compatible fittings.

- Result: New hoses are secure and leak-free under pressure. Hose compatibility and durability confirmed.

- Fixing Coolant Leakage (Water Pump and Thermostat)

- Objective: Resolved a coolant leak between the water pump and thermostat.

- Process: The coolant system was drained, components were inspected and gaskets replaced, and the system was refilled.

- Result: Leak resolved and coolant levels stabilized. Area will be monitored for potential recurrence.

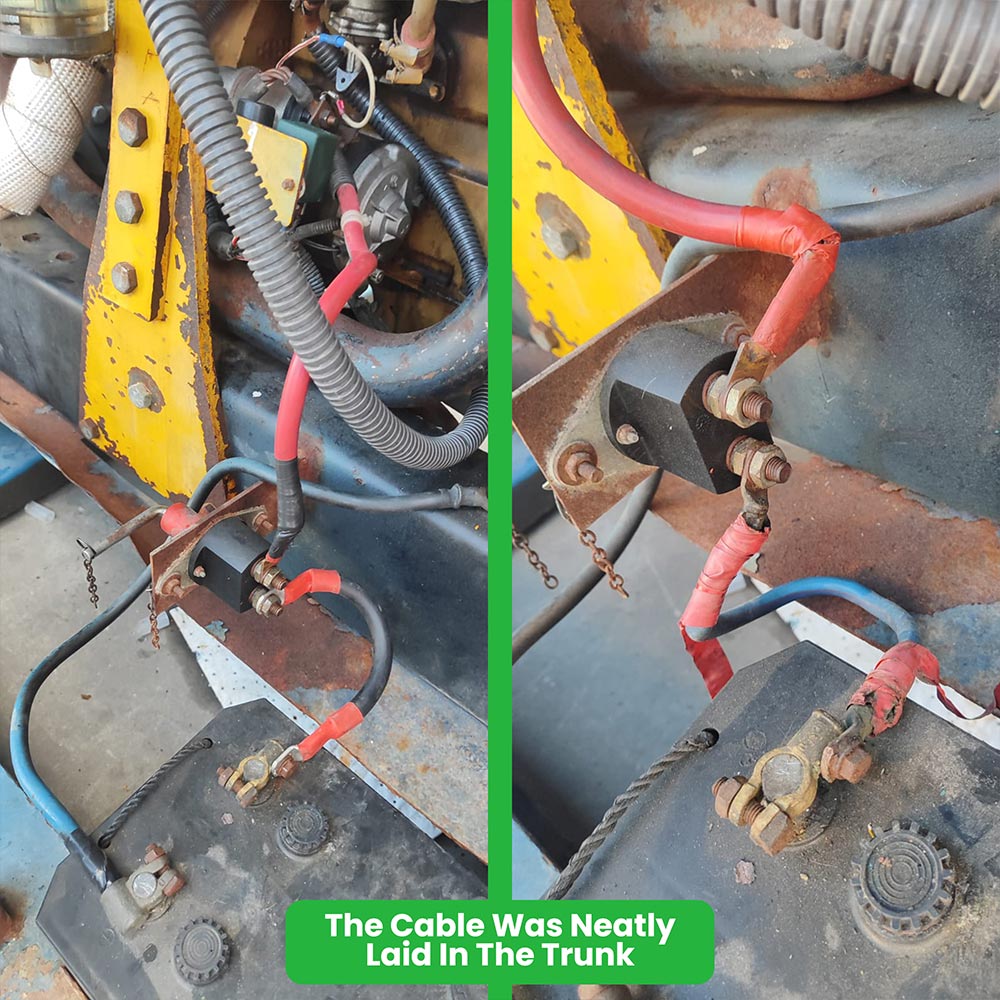

- Electrical Wiring Layout (Cable Management)

- Objective: Improved safety and accessibility by reorganizing and securing electrical wiring.

- Process: Identified and organized areas of wiring, securing them with clamps and ties for a clean layout.

- Result: Enhanced wiring organization, providing improved accessibility and safety. Regular re-inspection suggested.

- Provision and Installation of Electrical Clamps for Battery

- Objective: Enhanced battery connectivity and prevented disconnections.

- Process: Old clamps were removed, terminals cleaned, and new clamps installed with secure connections.

- Result: Stable battery connection confirmed, performing without issues during operational testing. Periodic checks recommended.

Each of these tasks contributes to a safer, more efficient, and reliable system. Our team is proud to have completed this project successfully, ensuring optimal performance and stability. Thank you for trusting us with your maintenance and system enhancement needs!