Leak sealing is critical to maintaining the integrity and productivity...

Read moreLeak Sealing Solutions

Spektr Group and KCI: Bringing Innovative Leak Sealing Solutions to Azerbaijan 🌟

Spektr Group has signed a partnership with Kinetics Controls & Innovation Limited (KCI) to introduce innovative leak sealant technology to Azerbaijan Oil and Gas sector, aiming to enhance oil and gas wells, prolong production, and solve integrity problems without stopping the productions.

These cutting-edge solutions, which have already saved major Middle Eastern exploration and production companies approximately USD 100 million collectively, are set to revolutionize well integrity management in our region.

The Challenge: In mature fields with aging wells, maintaining well integrity is a significant challenge. Harsh environments and corrosive well fluids exacerbate these issues, leading to costly well interventions and production deferments.

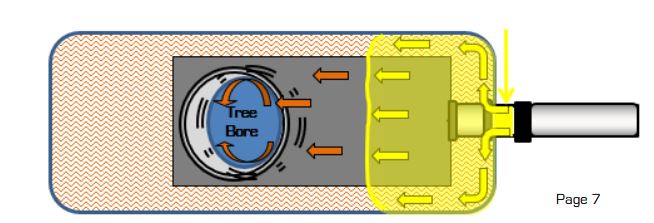

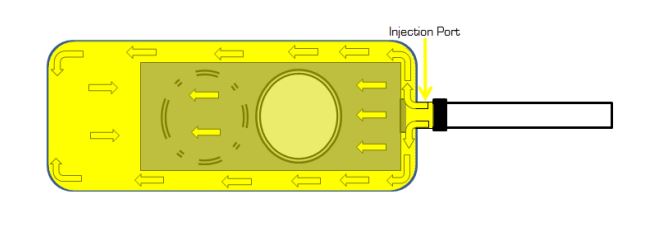

Solution: Innovative leak sealing technologies from Kinetics Controls & Innovation Limited (KCI), with whom we are proud to partner, use a time-activated sealant that, once deployed in its liquid phase, cures to a resilient, self-bonding solid material. These solutions act as static pressure-retaining barriers, ensuring the full integrity of wellheads and offering a reliable alternative to traditional methods.

Why This Matters:

Enhanced Safety: Provides a quick, safe, and effective repair solution.

Cost-Effective: Saves significant operational costs by eliminating the need for costly rig workovers.

Proven Success: With over 1000 jobs completed and a 99% success rate, this technology has proven its reliability and effectiveness.

Offered Solutions and Products

1. Well Head Isolations.

Mac-Seal-Two-part product. Activated by time. Solid yet flexible once cured. Available in various viscosities. Designed for cooler climate regions. (Mixing & Deployment temperature can reach up to + 30°C)

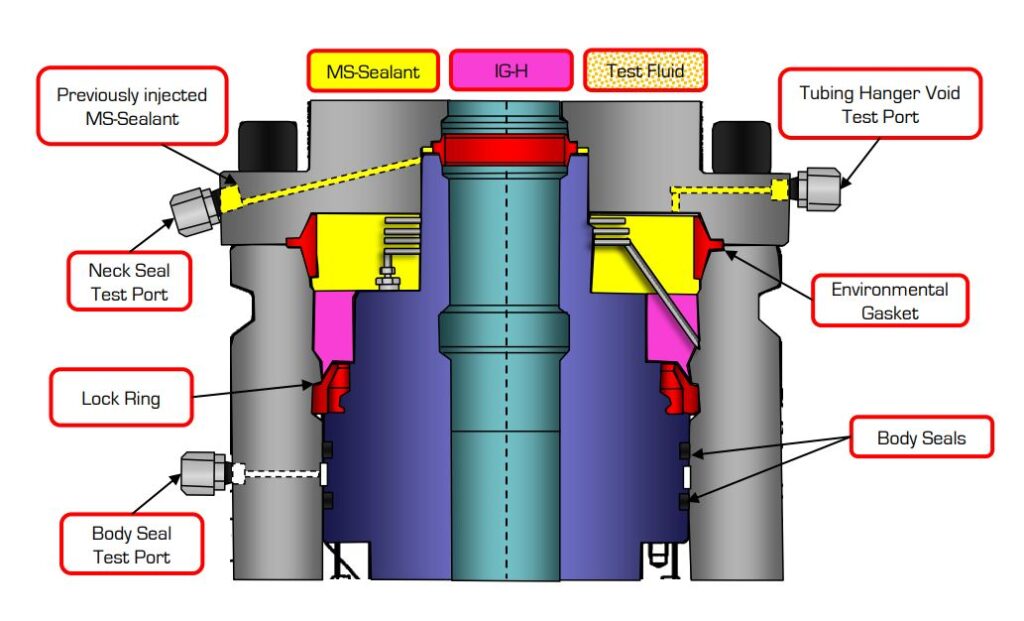

MS-Sealant– Two-component product. Activated over time, it becomes solid yet flexible when cured. Available in various viscosities and specially formulated for hotter climates. (Mixing & Deployment temperature can reach up to + 60°C)

Pressure Range– Perfect leak sealing solutions for high pressure cases up to 15k psi

Temperature Range– Operational temperature (-54 °C) up to (+260 °C)

Applications– Wellhead Seals, Tubing & Casing Hanger Seals, Wellhead Voids & Pack Offs, Tubing Hanger and Casing Hanger void full fill, Seal Assemblies leak isolations, 1 Port Access cases,and etc.

2. Gate Valve Isolations

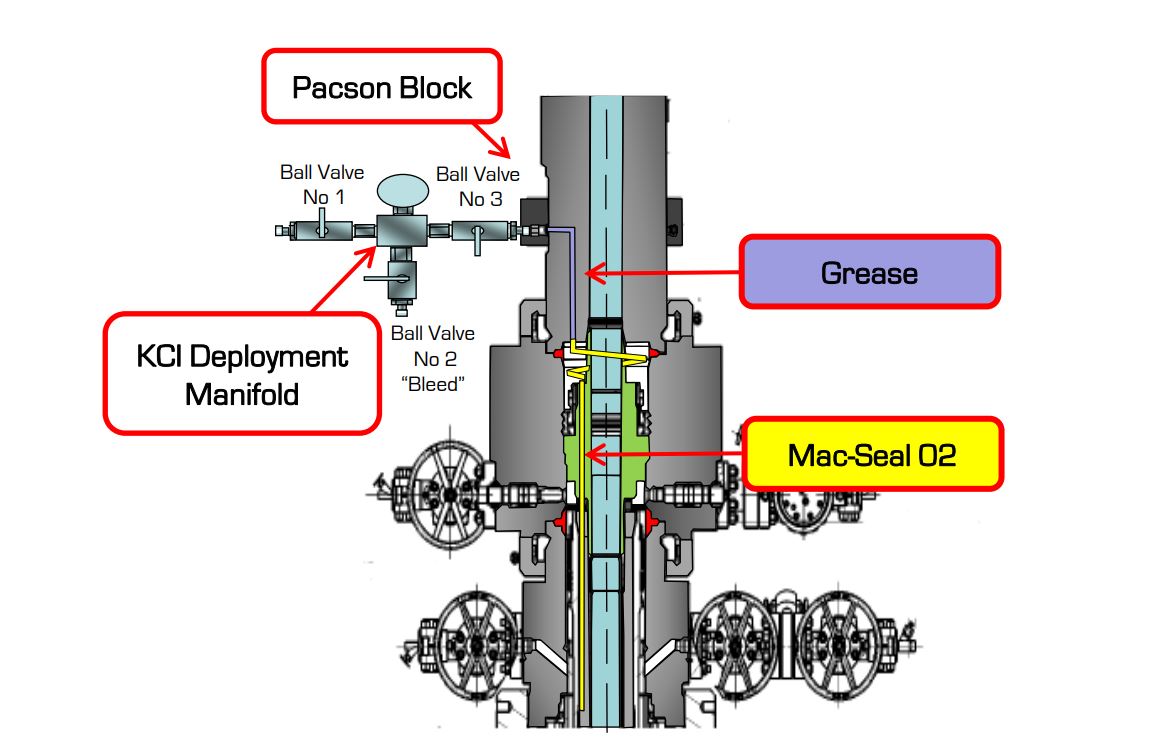

Mac-Pac- This is a one-part product designed as a non-curing sealant and lubricant. It features a high viscosity for effective application. Additionally, it remains stable across a wide temperature range, making it suitable for various environments.

It is an ideal replacement for general industrial grease, particularly in situations where traditional greasing fails to maintain pressure during emergencies.

Pressure Range– High Viscosity Sealing & Lubricating Compound sits within the valve cavity area that isolates most leaks

Temperature Range– Operational temperature (-50 °C) up to (+250 °C)

Applications-Damaged Sits, Failed Pressure Test, Leaking Steam Seal, Gate Valve Isolation & lubrication, could be replacement for P seals (Plastic Packing)

3. Control Line Leak Repair

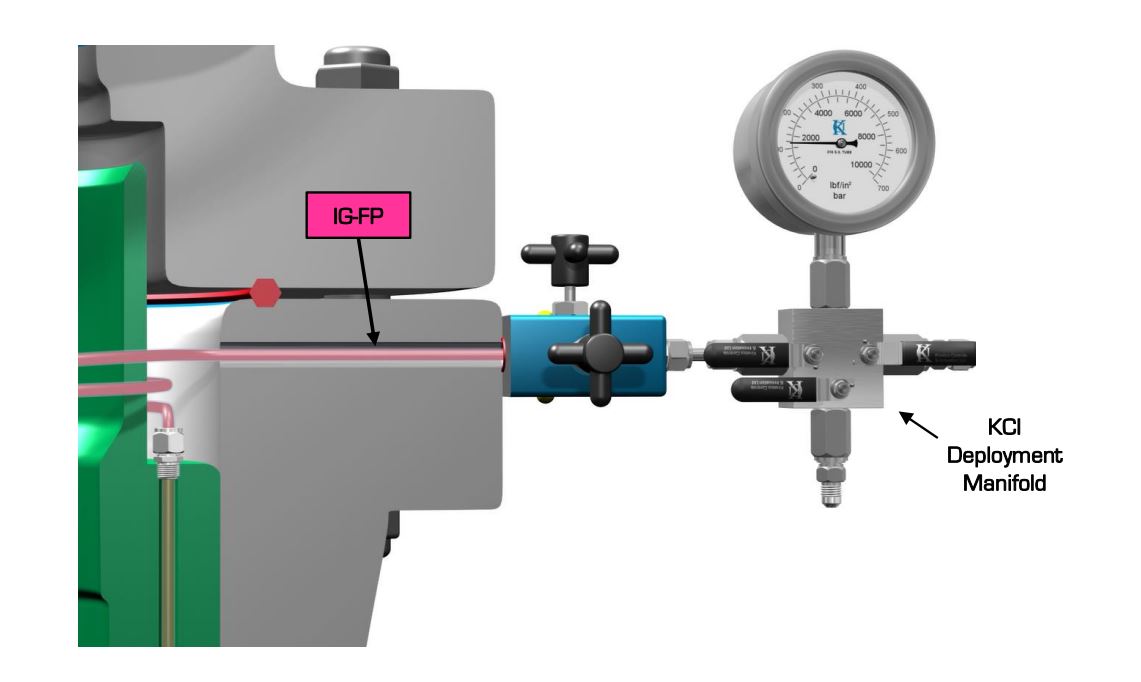

IG-FP (Isolation Gel- Fluid Piston)

This one-part, non-curing sealant is specifically designed to address hydraulic control line leaks in downhole safety valve (DHSV) compression fittings, effectively preventing hydraulic fluid from escaping the system while preserving the functionality of the DHSV.

It offers oil and gas well integrity teams a reliable alternative to pressure-activated sealants for this application

Pressure Range- The pre-activated tough gel can easily replace the operating fluid, restoring the functionality of the DHSV with its own pressure rating

Temperature Range– Operational temperature (-5°C) up to (+175 °C)

Applications-Control Line Leak Repairs, DHSV Control Line Repairs, DHSV piston area repair, Compression Fitting (Swage-Locks or any other) Leak repairs, Actuator Piston Seals repair and etc.

4. Control Line Blocking

In control line applications, Mac-Seal and MS-Sealant products are effective due to their compatibility with mixing and deployment temperatures. Control line plugging significantly reduces rig time and enhances safety during the pulling of completions. This method is more efficient than other operations, helping to prevent costly workovers or extended suspensions.

Pressure Range-Both Mac-Seal and MS-Sealant Leak sealing solutions designed for high-pressure applications can withstand effective pressures of up to 15,000 psi.

Temperature Range– Operational temperature (-54 °C) up to (+260 °C)

Applications: Control Line Blocking, DHSV Control Lines blocking, Chemical Injection Lines blocking, Capillary Strings or other Lines blocking and etc.

5. Packer and Sustained Casing Hanger Isolations

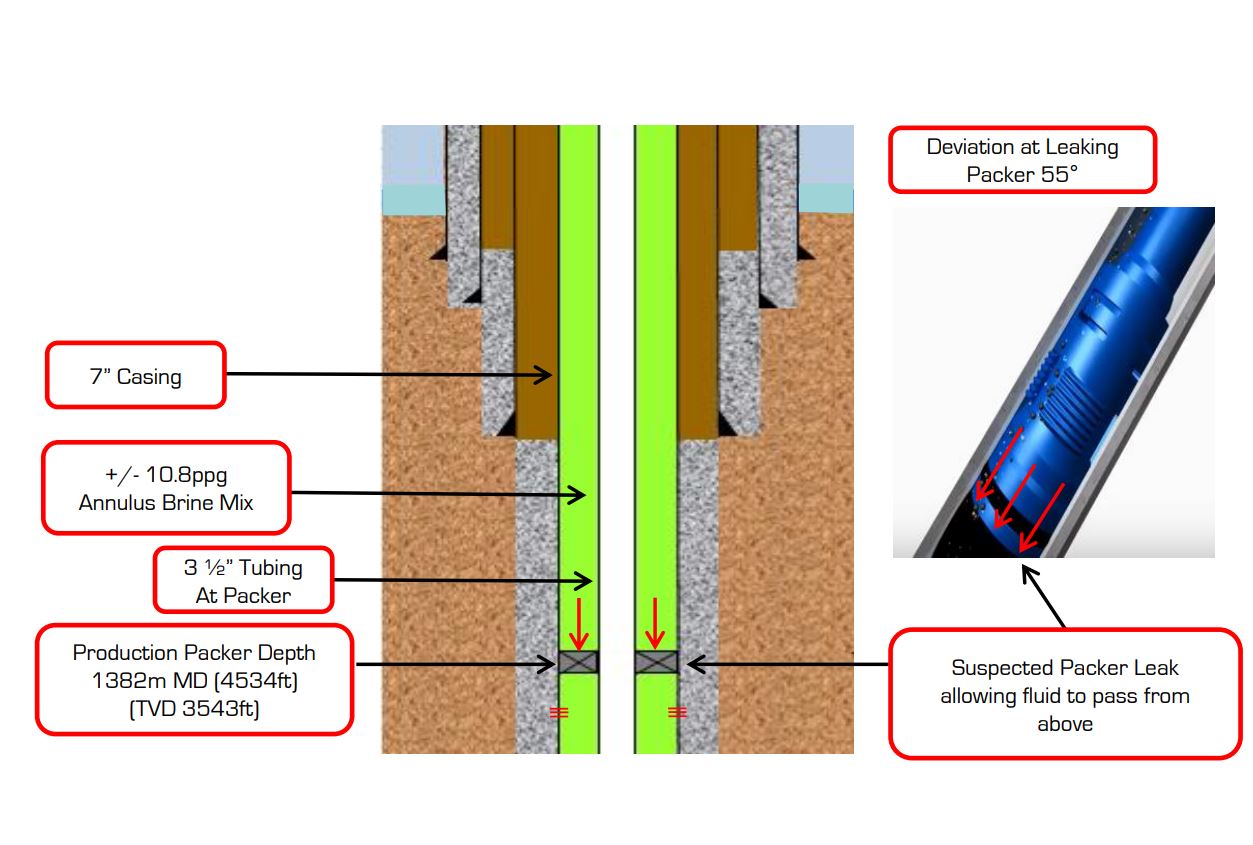

IG (Isolation- Gel) and IG-H (Isolation Gel – Heavy)- IG-H is engineered to effectively seal leaks in deep-set production packers where integrity has been lost and well pressure or fluids are accumulating. It is formulated as a weighted liquid gel, denser than the completion or annulus fluids, allowing it to sink to the bottom of the fluid-filled annulus. Accumulate on top of packer create plug and isolate the leak from bottom.

Pressure Range-it depends on lake rate, location and other factors however all our SCP jobs successfully completed.

Temperature Range– Operational temperature (-5°C) up to (+175°C)

Applications: Production Packer Leak repair, SCP-Sustain Casing Pressure (in A, B and C annulus), Casing Shoe isolations, Packer isolations

6. Ball Valves and Process Isolations.

IG-L (Isolation Gel-Light) is a time activated gel which deployed as a fluid, convert to a resilient, self-bonding, pressure energized, solid material to re-establish pressure retaining barriers. IG-L is a bit like a stress ball, soft yet solid. It can take huge compression forces but rips apart quite easily for removal purposes. IG-L has been formulated to float the top of a closed ball valve and cured IG-L can be converted back to a fluid state using the IG breaker solution and then flushed out. The IG breaker is a 97% water-based solution and will convert the cured IG-L back to an aqueous solution. Or simple pigged out in its solid form.

You can also visit our LinkedIn account to see more works.

News

Spektr Group and Kinetics Controls & Innovation Ltd. Join Forces in Azerbaijan’s Oil and Gas Industry

The partnership between Spektr Group and Kinetics Controls & Innovation...

Read more